Introduction

The cost of the power outage to a business can be considerable, including the loss in a product, revenue, efficiency, and customers. To cope with this, businesses such as Factories, Warehouses, Food Processing Plants & other Industries, Data Centers, Hospitals, Airports, Police Stations, Fire Stations, Petrol Pumps, Oil & Gas Refineries, Malls, Research Labs, Schools & Universities, and others, install multiple generators / multiple storage tank fuel systems for consistent backup power. If no fuel is available to the generator during power outages, then the purpose of the generator is lost. Hence it is essential to store fuel so that such a case does not arise.

The fuel system is designed to safely store fuel and transfer it to the generators when needed. Large fuel volumes are stored to allow for long run times creating a challenge to maintain fuel quality. Manually examining tank fill-level, tank alarms etc. is time-consuming, costly, and highly error-prone, which can completely freeze operations, making fuel monitoring a necessary part of many businesses.

Thus, to regularly monitor fuel tank sensors are used like ultrasound or radar, to identify tank fill-levels and report them to managers in real-time. They get alerts immediately of issues like tank leaks or theft when any typical changes in fuel level is found. Hence, managers can better optimize inventory management and schedule services to improve working efficiency, ensuring that they receive every refilling right when they need it.

Tank level monitoring systems allow users to remotely gather data from multiple tanks across buildings with the same high level of accuracy every time, eliminating manual errors and training managers with the information they need to improve efficiency.

The fuel management platforms like Banlaw, Gilbarco Veeder Root tank gauge have a huge range of products like TLS4, TLS4B, TLS-450 PLUS, TLS-350, TLS-XB, etc., OPW tank gauge having products like Site Sentinel Nano, Site Sentinel iTouch, Site Sentinel Integra 500, etc. are there in the market to serve best results to businesses.

Challenge

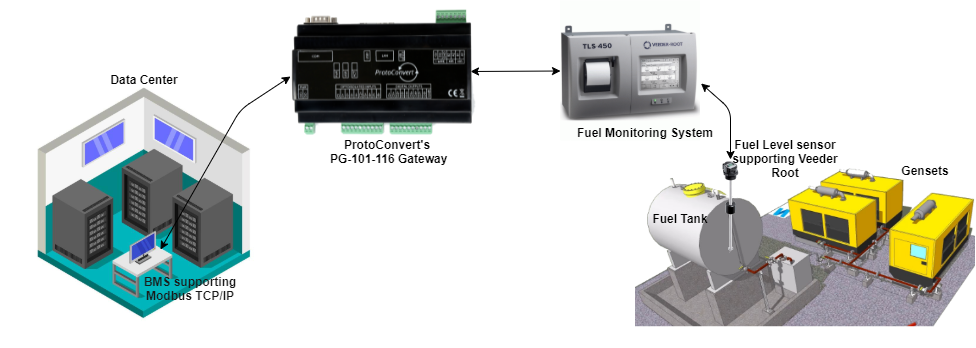

Data Centers require reliable and complex fuel systems to assure uninterrupted power supply to computing functions. There should be no room for downtime in a data center. This requires extensive integration with building management systems (BMS) to allow long-term efficient facility operations.

Based in Singapore, an Amazon Data Center have a huge Fuel Gauge System for their power backups. Our experts successfully integrated their fuel sensors to BMS to measure tank levels, tank alarms, sensor alarms, etc. The challenge was to test and integrate all Fuel Gauge status points into the BMS system.

The fuel system data was to be monitored and controlled on third-party BMS. It was not possible to directly connect the sensors installed in the fuel tanks and the BMS as both supported different protocols.

Dedicated Remote Monitoring and Management Platform

Businesses incur a lot of loss due to unplanned downtime. It is never a good thing when Data centers experience unexpected halts.

Shubham International Inc. develops the top leading BMS for an easier and safer life. It provides the data and controls need to use by utilizing your existing infrastructure resources. Our PG 101-116 gateway was deployed this year at the Amazon Data Center in Singapore to monitor and control data using their existing fuel management infrastructure.

The sensors installed in its fuel tank supported the Veeder Root protocol. While the OPW’s Site Sentinel Nano BMS supported Modbus TCP/IP. It was not possible to directly connect the sensors and the BMS as both supported different protocols. Here comes the vital role of our gateways to convert required protocols using existing resources without altering your infrastructure and hence saving the cost to be incurred with changing the whole existing system.

Our gateway served as a boon to them as they could successfully fetch the required data from the fuel tank that worked on Veeder root and get it displayed on BMS that supported Modbus TCP/IP and could cater the unexpected downtime to their business.

Conclusion

This customized solution can be implemented in processes where remote monitoring integration is required in building automation. The solution replaces the existing SCADA fuel management system to one which is much more energy efficient, and safe integrated remote monitoring system. This system is custom designed considering your process requirements. As a result, you can experience benefits of your existing system at a lower cost.

Shubham International Inc. has over 10 years of experience and expertise in integrating devices on standard protocols like BACnet, Modbus, Lon Works, SNMP, JCI Metasys N2, KNX, Veeder Root, Agilent, OPC DA/UA, M-Bus, and many others. We also have a range of IIoT Solutions on JSON, XML, MQTT, Telnet, Data Logger & SCADA, SMS, Email solutions, and many more. If you want data from your field devices on the cloud or want to monitor/control them using the internet, then we have the right solution for you. We can also develop custom interface solutions for the integration of devices that use proprietary protocols. No matter how complex the problem is, we are committed to applying all our resources to engineer the best possible solution.